Current Projects

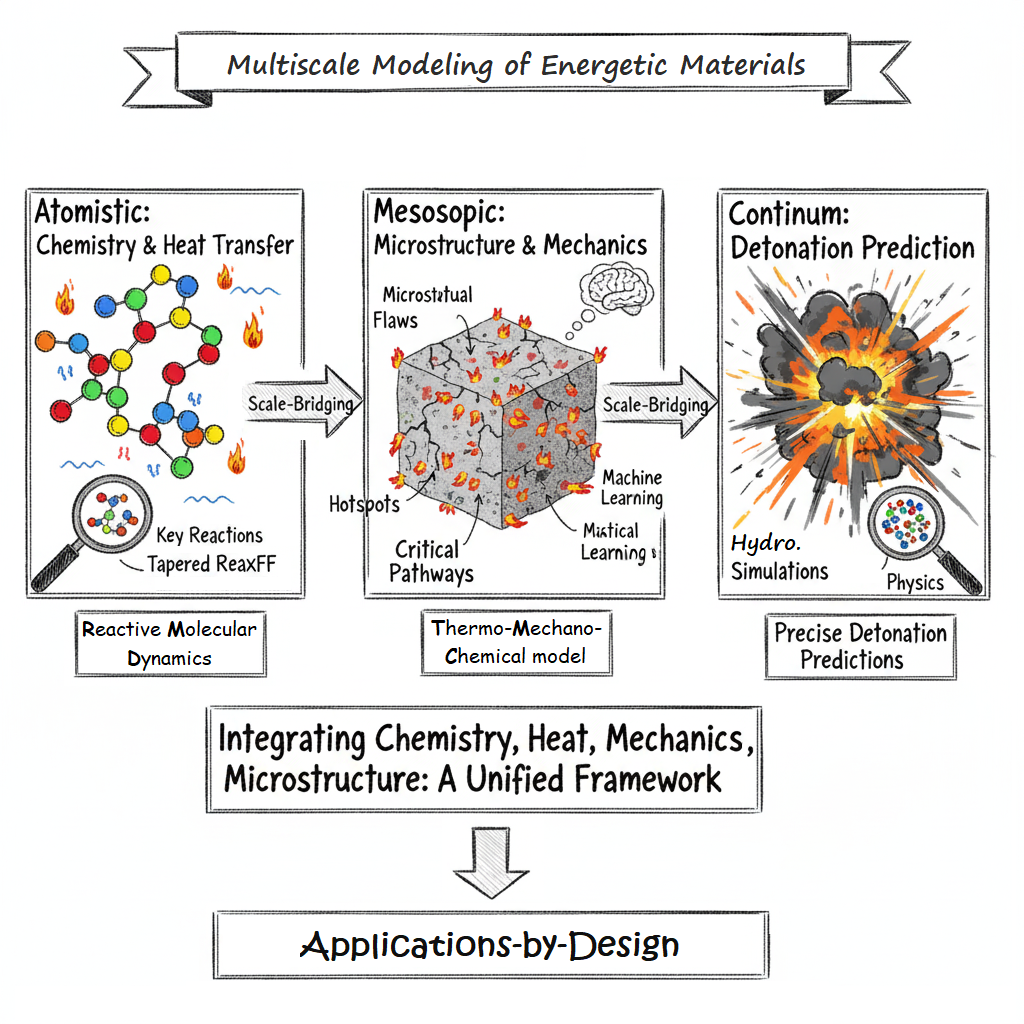

1. Hierarchical simulation of energetic materialsOur research builds a comprehensive understanding of energetic materials from the ground up using a hierarchical, multiscale modeling approach. We begin at the fundamental level, simulating atomic and molecular interactions to capture the chemistry that drives energy release. From there, we scale up to the mesoscopic level, modeling the behavior of grains, defects, and hotspots, which are critical in determining how and when a material will ignite. Finally, these insights are integrated into continuum-level hydrodynamic models that describe the propagation of detonation waves. By bridging these scales, we create a seamless predictive framework that moves beyond empirical models, enabling the design of safer and more reliable energetic materials from first principles. |

|

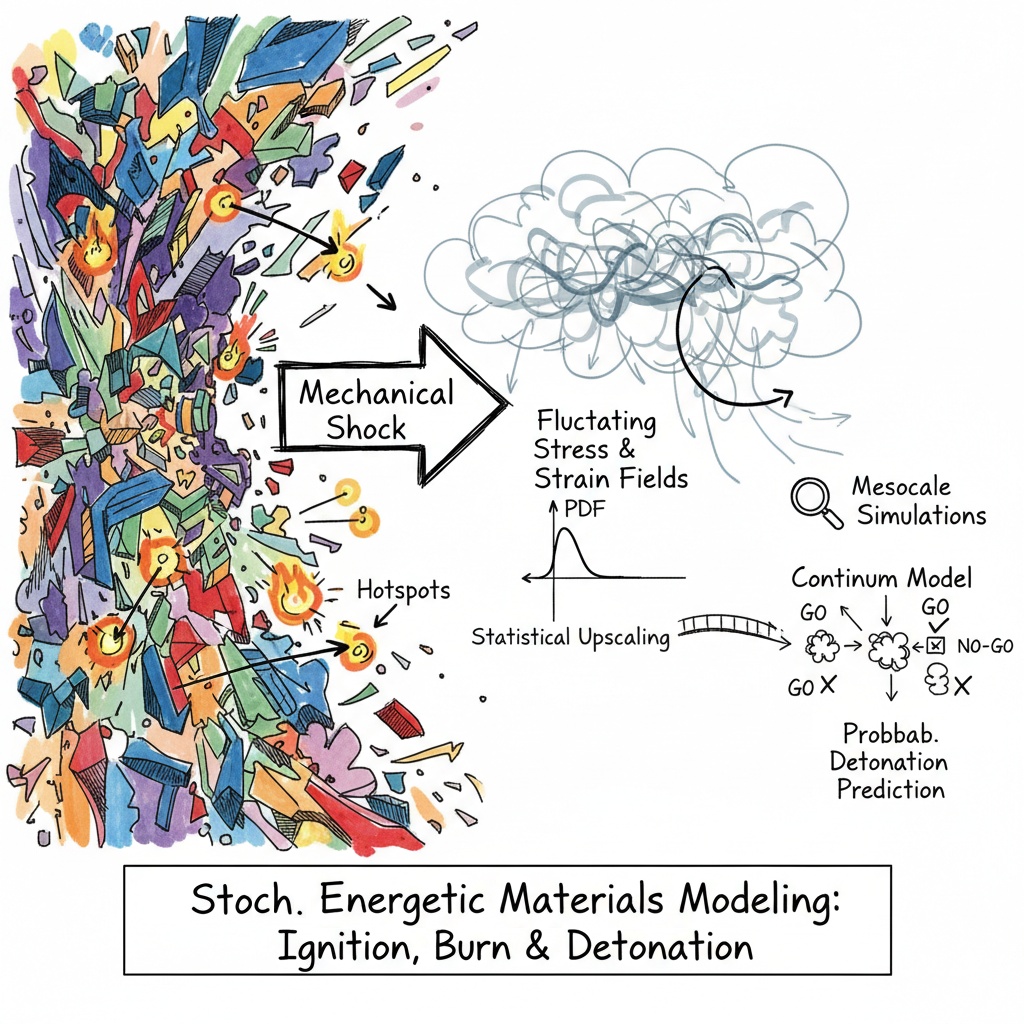

2. Stochastic models of ignitionThe performance of energetic materials is often unpredictable, as small-scale inconsistencies in their structure and environment can lead to surprisingly large variations in behavior. Conventional deterministic models fail to capture this inherent randomness. Our research addresses this gap by developing stochastic models that embrace this uncertainty. We focus on how random events at the micro- and meso-scales—such as within individual grains—govern critical phenomena like ignition and the propagation of burn fronts. By shifting from a purely deterministic to a stochastic viewpoint, we aim to create more robust and predictive models that account for the real-world variability of these complex materials. |

|

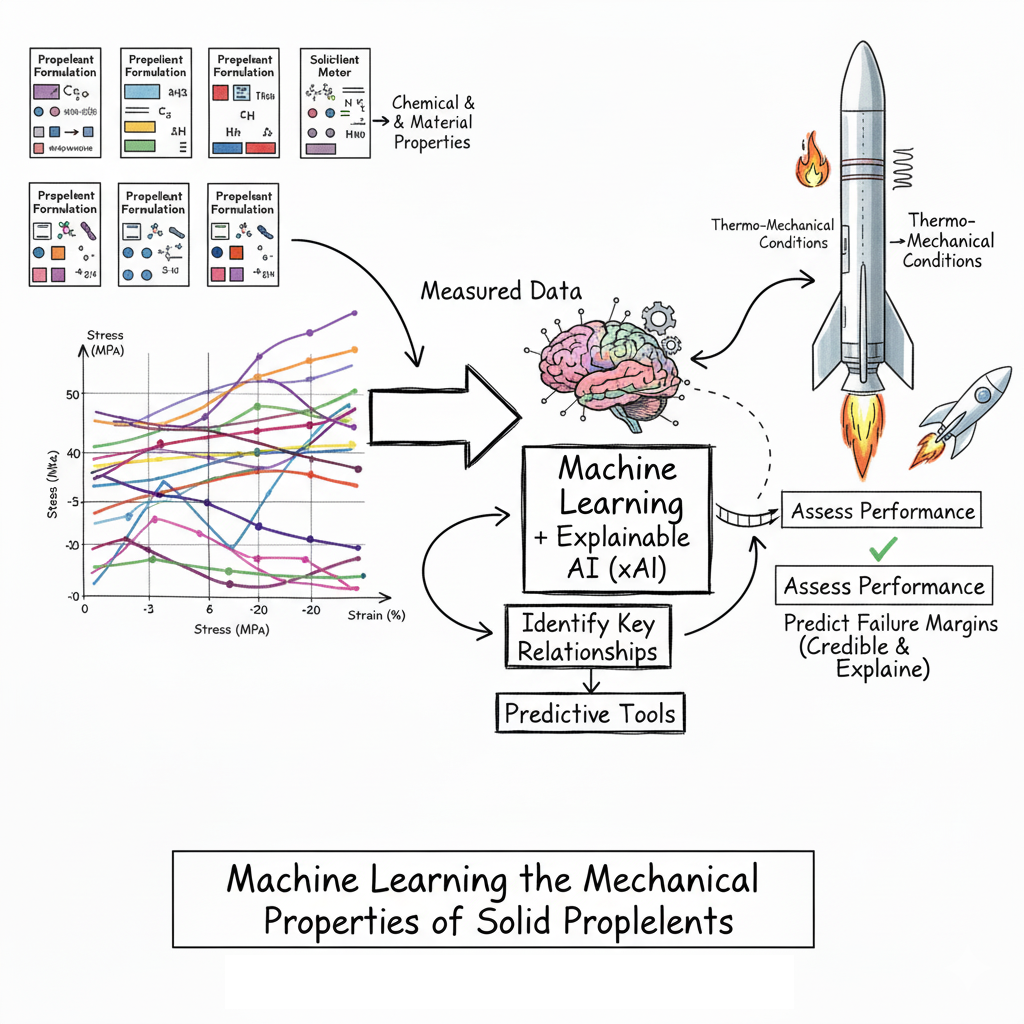

3. Machine Learning Solid PropellantsThe reliability of solid propellants hinges on their mechanical integrity, but predicting how a propellant will behave based on its chemical makeup is a notoriously difficult problem. Our research uses machine learning to tackle this challenge head-on. By training algorithms on vast datasets of propellant formulations and their experimentally measured stress-strain responses, we uncover the subtle, data-driven relationships between chemistry and performance. The goal is to move beyond trial-and-error, creating predictive models that not only ensure reliability under demanding operational conditions but also reveal fundamental design rules for creating the next generation of advanced propellants. |

|

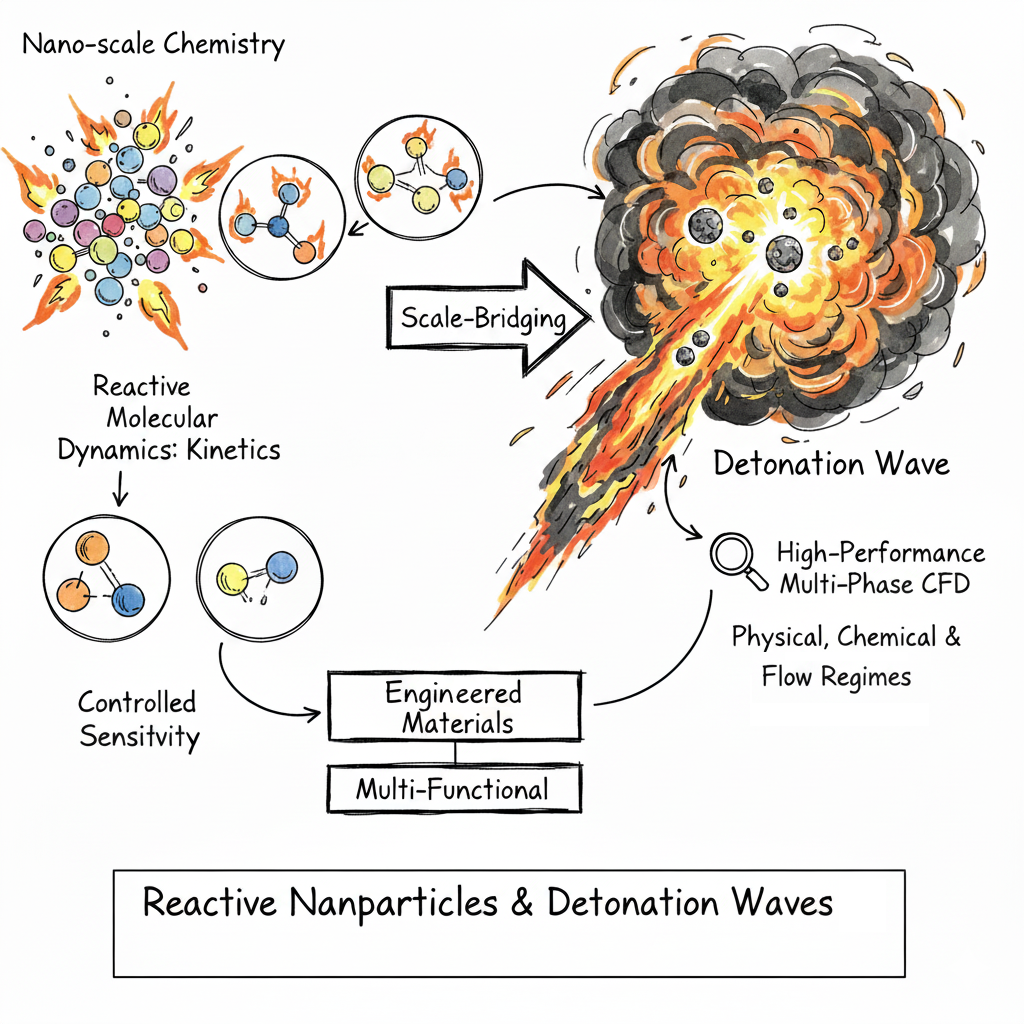

4. Functional MaterialsThis research focuses on the modeling of functional materials with tailored properties. We explore a range of advanced materials, including high-entropy alloys and metallic nanoparticles for energetic applications. By combining large-scale molecular simulations, multiphase hydrodynamic models and theory, we aim to understand and predict material behavior under extreme conditions. One key area is investigating how metallic nanoparticles, like aluminum, can enhance the performance of energetic materials by optimizing their interaction with detonation waves. Another focus is the discovery of novel high-entropy materials with exceptional properties. We also study MAX phases, a class of nanolaminated materials that combine metallic and ceramic properties, to understand their anomalous energy release and unique response to shockwaves. These projects integrate modeling with experimental collaborations to accelerate the design of next-generation functional materials. |

|